As digital transformation drives the printing industry, photopolymer plate makers have become an essential tool for print shops and industry professionals. These devices offer incredible precision and quality, simplifying the process of creating print designs on varying mediums.

However, with the broad range of models and price points in the market, it can be challenging to identify a photopolymer plate maker that offers both quality and affordability. The following are six essential tips to guide your purchasing decision.

Know Your Specific Needs:

Every photopolymer plate maker is designed to fulfill a specific set of tasks. Some are ideal for letterpress, flexography, or printing on irregular surfaces, while others are more suitable for more detailed and intricate work, such as circuit board manufacturing or fine art printmaking. Before you start comparing prices and features, have a clear understanding of your needs and requirements.

Research the Manufacturer:

When investing in machinery, it’s essential to research the manufacturer. Find out how long they have been in business, their reputation in the market, and read reviews from other users. Established manufacturers often provide better customer support, warranties, and high-quality machinery.

Consider the Technology:

Photopolymer plate makers employ different types of technologies. For instance, some use UV exposure while others use LED. Research the benefits and drawbacks of each technology and choose one that aligns with your specific needs and the nature of your tasks. Newer technology might offer more efficiency, precision, and longevity, but could come with a higher price tag.

Assess the Features:

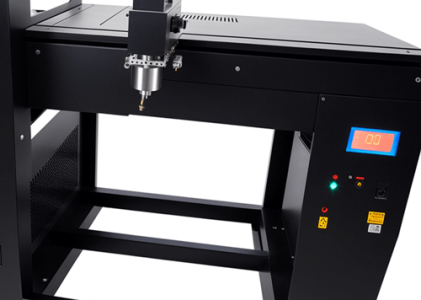

Look out for features that can make the photopolymer plate making process more efficient and accurate. These might include adjustable exposure times, temperature controls, and a user-friendly interface. Also, consider the size of the machine. If your business handles large printing projects, you’ll need a plate maker with a larger plate capacity.

Look at the Total Cost of Ownership:

While the upfront cost of the photopolymer plate maker is an important consideration, don’t forget to evaluate the total cost of ownership. This includes the cost of consumables such as photopolymer plates, cleaning agents, and bulbs for UV exposure units. Additionally, factor in energy consumption, maintenance, and potential repair costs.

This website has got some of the best quality photopolymer plate makers.